Raschig Ring

Release date: 2015-10-11 & Source: & Views: 1670

Raschig ring is the earliest developed random packing, named after the German chemist Friedrich Raschig. It''''''''s small tube cutting, which outside diameter is equal to its height, providing a surface for (re)evaporation of the most volatile part in the refluxing distillate, typically 10 mm in diameter and 12 mm long.

Raschig ring is the earliest developed random packing, named after the German chemist Friedrich Raschig. It''''''''s small tube cutting, which outside diameter is equal to its height, providing a surface for (re)evaporation of the most volatile part in the refluxing distillate, typically 10 mm in diameter and 12 mm long.

It''''''''s used in commercial fractional distillation towers to reduce pressure loss (versus using trays), while maintaining good efficiency and economy. Typically the change in pressure (also called "delta p") is lower than in the case of trays but slightly higher than for structured packing.

With the characters of high mechanical strength, high chemical stability, and excellent heat endurance, Ceramic Raschig Ring can resist high temperature, acid (except HF), alkali, salt and various organic solvents. It''''''''s widely applied in various packing towers of desiccation, absorption, cooling, washing, and regeneration in industries of petrochemical, chemical, metallurgy, gas and oxygen generation.

For raschig ring with big size over 100mm, it''''''''s usually filled in the column orderly. If its size is less than 90mm, raschig ring is stacked in the column randomly.

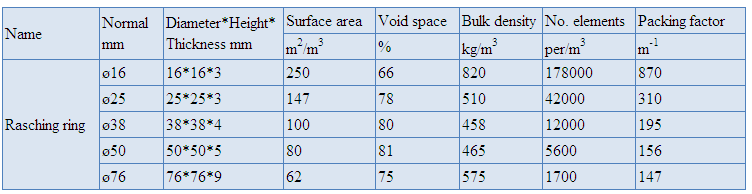

Technical date: