1. Detailed

introduction

1. Detailed

introduction

palladium based catalyst PGH-10 for first-stage

hydrogenation of pyrolysis gasoline

PGH-10 serials catalysts for first-stage hydrogenation of

pyrolysis gasoline, composed of noble metal palladium as active component and aluminum oxide as

support with adding of various additives, were mainly used in the selective

hydrogenation of pyrolysis gasoline C6~C7,

C6~C8, C5~C9, which were the

cracking byproducts in the process of ethylene production.

In order to meet the market demand, PGH-10A, a new brand

catalyst for the first-stage hydrogenation of pyrolysis gasoline, was developed

by our company at the beginning

of this century. PGH-10A made greater improvement in water resistant,

anti-arsenic, sulfur-tolerant and hydrogenation stability, etc. It was

industrial applied successfully in the petrol devices of Yanshan

Petrochemical, Shanghai Petrochemical, Lanzhou Petrochemical.

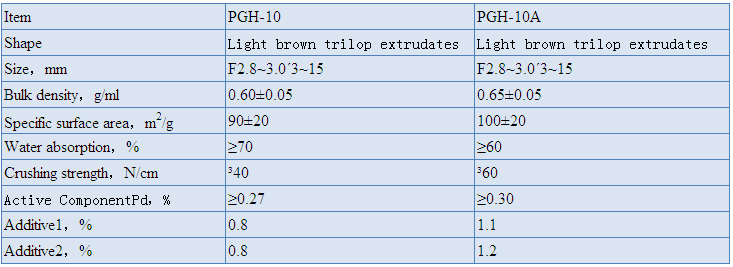

2. Physical and chemical properties

Comparison

of PGH-10 and PGH-10A

The combination of support,active component and additive

in PGH-10A was more favorable to pyrolysis gasoline hydrogenation.PGH-10A has

not only high chemical stability, high thermal stability and low rate of carbon formation, but

also good hydrogenation,anti-water, anti-impurities, anti-high-load

performance.

3. Catalyst Use Claims

3.1 Catalyst Process Operating

Conditions

operating

pressure(MPa)

≥2.4

inlet temperature (℃) initial 30~50,end 90~110

hydrogen-oil ratio (fresh feed)

(V)

60~120

space velocity (fresh

oil) (h-1)

≤3.5

3.2 Composition of

Hydrogenation Raw Oil

3.2.1 Disposal Oil

distillate

C6~ C8、C5~C9

boiling range (℃)

50~175

diene content (gI2/100g.oil)

≤35

bromine number(gBr2/100g.oil)

≤70

arsenic

content(ppb)

≤20

gum content (mg/100ml)

≤10

inorganic sulfur content

(ppm)

≤3

water

content(ppm)

≤400

3.2.2 Hydrogen

purity(v%)

≥85

methane

Balance

CO+CO2(ppm)

≤5

3.2..3 Hydrogenation Product

Index and Catalyst Lifetime

hydrogenation Product diene(gI2/100g.oil)

≤2.5

catalyst guarantee lifetime

24months

first run

cycle

≥12months

4. Comparative Evaluation of PGH-10A

with competitive Catalyst

1000 h Comparative evaluation test of PGH-10A and competitive catalyst were

carried in 100ml Insulation installation. The details were showed in following:

4.1 Evaluation Device

catalyst bed temperature of the evaluation device which

was imported from Xytel companies USA was controlled in three sessions. The temperature

difference of insulation bed reactor was < ±0.5 ℃ between inside and outside.

Raw materials oil, hydrogen were injected into the pre-heater and mixted. when

the temperature of the mixture reached the target temperature,operating

parameters were tracking controlled automatically by a computer. The reaction

products were isolated after condensation: oil was injected into the product

tank, exhaust gas was emptyed after measurement and the bromine number

and diene value of oil were analysized.

4.2 Conditions of technological

Evaluation

Operating pressure: 2.8MPa Inlet temperature:

35~65℃

Liquid hourly space velocity: 3.5h-1 Hydrogen-oil ratio: 80:1(Vol)

4.3 Evaluation Materials

Raw materials oil was the whole distillate oil C5~C9 pyrolysis gasoline and its properties were showed in Table follows.

Properties of Raw materials oil

4.4 Evaluation results

1000 h Comparative evaluation test of PGH-10A and competitive catalyst were

carried in 100ml Insulation installation. The result was showed in following:

Figure 1 Comparative evaluation results of the

hydrogenation product diene value with time on stream catalyzed by PGH-10A

and competitive catalyst1000 hours operation process(the diene value of raw

materials was up to 42.53gI/100g and bromine number to 104.2gBr2/100g)

indicated PGH-10A was adapted to low-grade oil and good hydrogenation

performance and its catalytic activity was considerable to competitive catalyst

in Figure 1. PGH-10A has a good hydrogenation performance and stability.